Despite the business challenges faced amidst the COVID-19 crisis, to ensure it can deliver the most premium fencing solutions possible Zaun has made an important investment to purchase new technology that is literally “cutting-edge.”

To answer our ongoing productivity requirements Zaun has now purchased a brand new Adige LT7 fibre laser, described by its designers as part of “The new generation in tubes laser cutting.”

This state-of-the-art solution will enable us to not only replace the laser’s predecessor but enhance productivity and work even more efficiently than ever before.

Upgrading a key component in Zaun operations

The laser currently used at Zaun is an integral part of our production process but due to its age, it has been struggling with reliability issues. With its significance recognised as being critical to how we operate, the decision was taken to make an investment in not simply a like-for-like but a substantial upgrade, by purchasing a more current cutting machine with improved capabilities.

Selecting the right substitution

Technical experts at Zaun conducted extensive research to find the ideal laser cutter. Future proofing our business is a critical element when making a sizeable investment in any piece of key equipment, so the solution selected needed to offer not just high-quality laser cutting but be well-built to serve our requirements as we continue to expand. That’s why the Adige LT7 fibre laser was chosen for its superior design as well as its high-tech bevel cutting abilities and advanced attributes working with flats, angles, and channels.

Work to be executed by the new fibre tube laser cutter

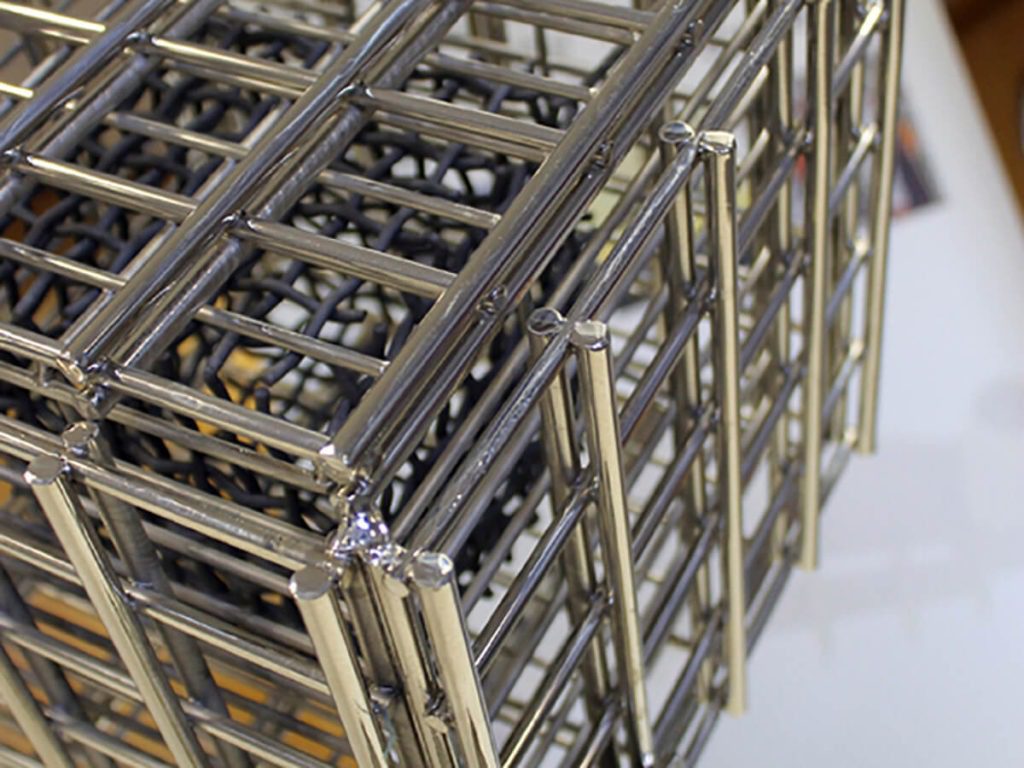

Once installed, the Adige LT7 fibre laser cutter will be used by Zaun to produce the parts for its extensive range of security perimeter solutions that have served in many high-profile and prestigious installations across the country. Topping brackets, fencing posts, gate frames and other requirements for our fortified fencing systems will all be cut with perfect precision by the latest advances in laser cutting technology.

Enhanced precision and productivity with the Adige LT7 fibre laser

Exceptionally versatile, the LT7 boasts a broad range of tube processing and can cut square, round or rectangular tubes with ease. It benefits from 6.5m out-feed and is capable of cutting up to 150×150 square. Productivity-wise it also excels with cutting accuracy never compromised even at high accelerations on account of the robust mechanics of its system, ideal for boosting processing times of tubes and profiles. Work speed is enhanced further by active tilt for the cutting head that enables operators to quickly cut materials with a thin wall.

Production is also improved as both long or short pieces can be unloaded from the rear or front of the cutting equipment, separating any scraps without ever needing to halt the work cycle.

The LT7 also has the advantage of 360° flexibility allowing operators to use the beam loader and work independently. Open or special profiles can be loaded easily or small batches of only a few bars added, perfect for limited production quantities.

Entirely automatic, no machine stops are necessary. After the end of every batch, the LT7 resets for the following cycle with its loader, front bezel, rear spindle along with its intermediate supporters all adapting automatically to the next section required to be cut.

The LT7 can also be configured to work around the clock seven days a week to optimise output. In seconds, its unloading chains can be easily detached from its rear loader and connected instead to an automatic store and robotic loading system.

Automatic loading requires no manual adjustment to the machine’s rear loader over its multiple sections. The LT7 is fully accessible from the upper and rear side so operators can load material directly with forklift or bridge crane.

High dependability can be achieved for any type of tube. The LT7 has self-adjusting guides that can adapt instantly to the weight and dimension of any tube requiring cutting. From flexible lighter tubes to heavier and more rigid items all can be cut with expert precision to make the specific elements required for of our security fences.

Adopting new technology to help those we serve

At Zaun we are constantly evaluating the way we work and the fencing options we produce so we can evolve and improve the service we provide. Keeping informed of the latest technological advances for industrial processes allows us to make selections that can benefit our customers as we offer a more seamless service, installing more refined and robust security solutions, perfectly cut to order.

Whether you’re maintaining health and safety rules while operating a construction site or protecting pupils at a school or college, if you require perimeter security fencing contact us for advice and suitable solutions.